Maria Kuptsova

ARBOR

2021ARBOR is a cyborganic living object, bio-artificially grown by the means of intelligent technologies.It is a regenerative system, where overall organism is alive and where the concept of living involves both biological and technological forms.The project outlines an approach for reading the intelligence of an organic timber structure, as well as rethinks the life cycle of wood, proposing a bio-artificial system which is alive in a cybernetic sense.

If we look at the microscopical pattern of wood we would see a great level of complexity embedded within its structure. It contains information about intelligent mechanisms of photosynthesis, growth, water and food distribution. ‘Biological structures adapt to external stimuli by growth-induced material property variation resulting in hierarchically structured forms. Shape results from bottom-up material organization, sophisticated property gradation and functional hierarchies developed over time within single material systems’ (1).The anisotropic properties are crucial characteristics of timber structure which represents its constant and reciprocal interaction with the surrounding environment. These qualities, which are usually considered as negative side effects, can be rethought and reused in a design of artificially alive systems which are capable to interact with the environment and develop functional capacities through this interaction.The project outlines an approach for reading the heterogeneous properties possessed by wood in its living state by the means of machine learning algorithms in order to embed its logic into a digital form. This method allows to design a hybrid materiality which hosts biological intelligence within the digital structure.

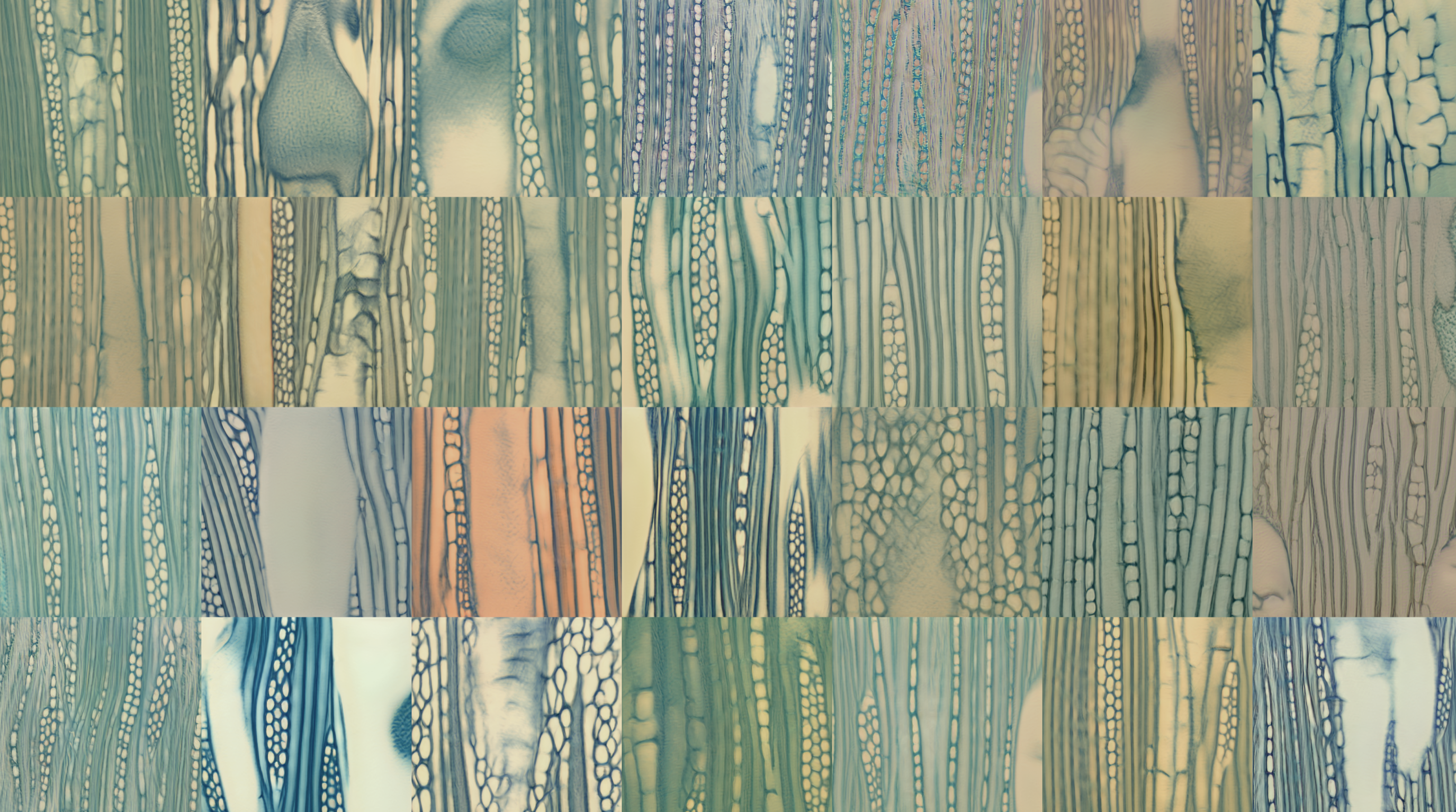

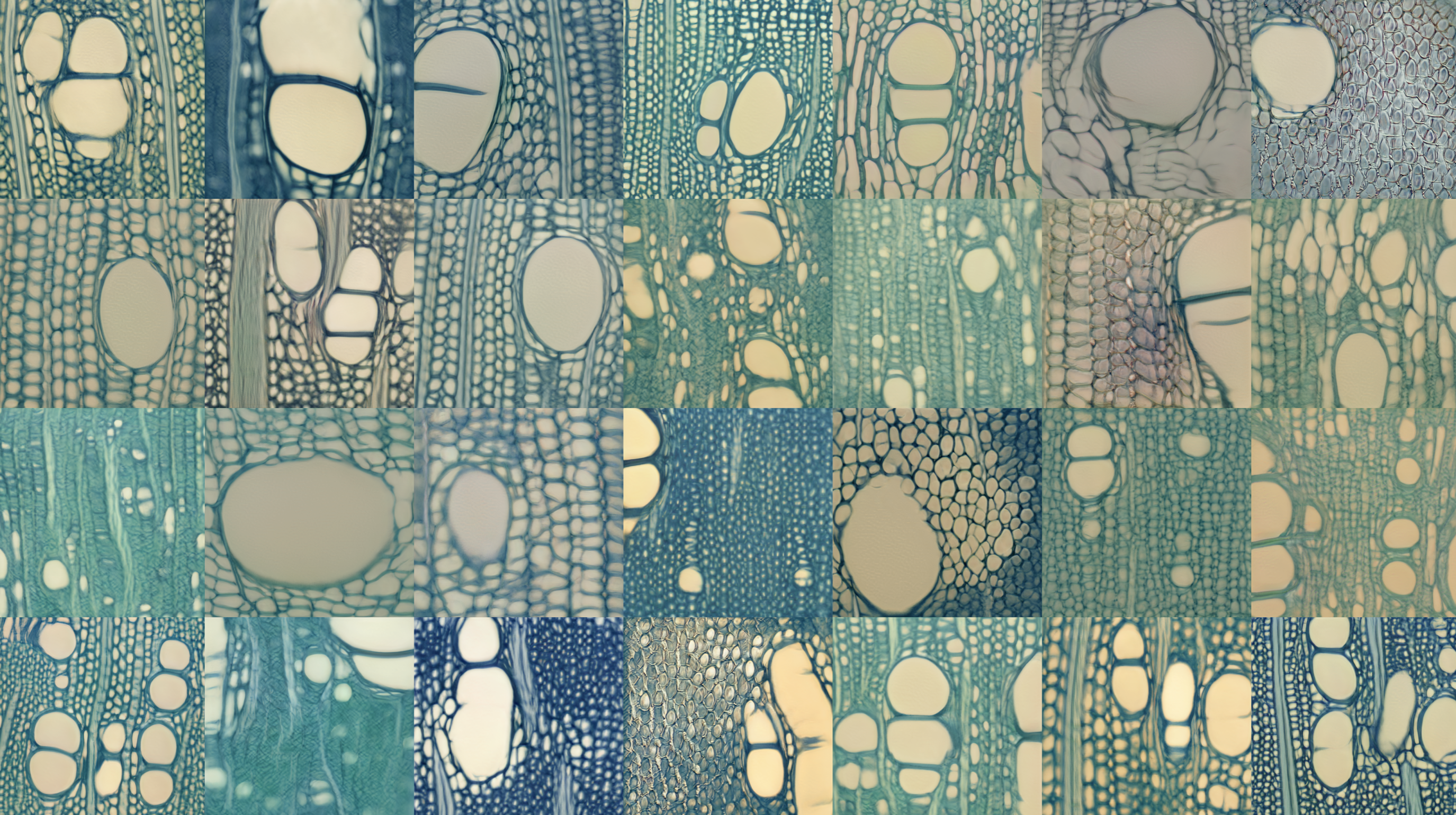

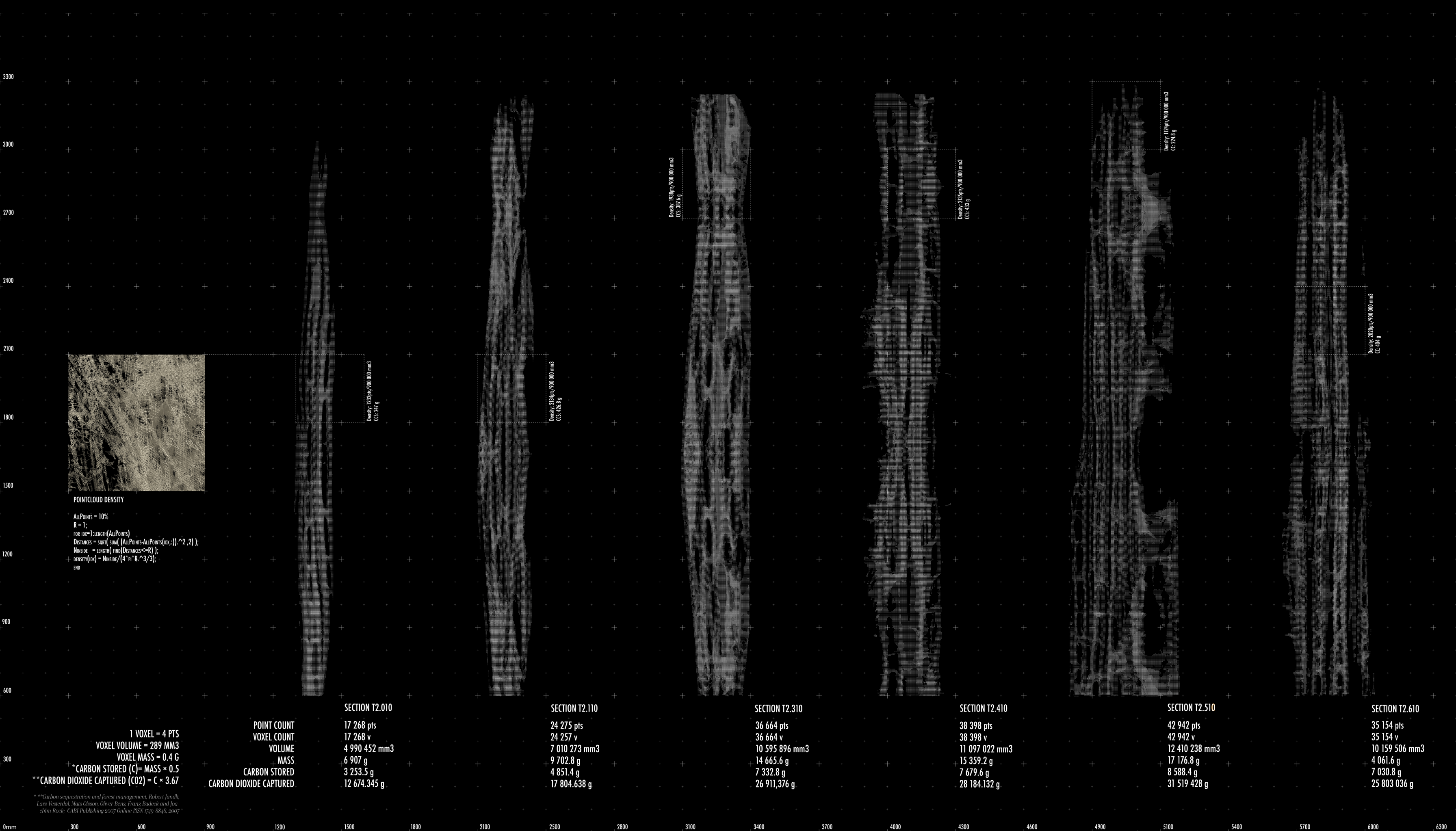

To study the material organization of wood the project uses the large dataset on the botanical characteristics of different wood species developed by the ArchiWood project (2). Micro images of 995 species were collected and analysed with different contrasting techniques. ‘For each wood species, there are 3 anatomical cuts associated with the 3 planes of symmetry of the material taken in 3 different magnifications of the microscope: x40 (overview of the cut), x200 (main features anatomical from IAWA), x400 (highlighting fine lines such as punctuations)’ (3).

StyleGAN interpolation. CTL Tangential anatomical cut. x200

StyleGAN interpolation. CT Transversal anatomical cut. x200

StyleGAN interpolation. CT Transversal anatomical cut. x200

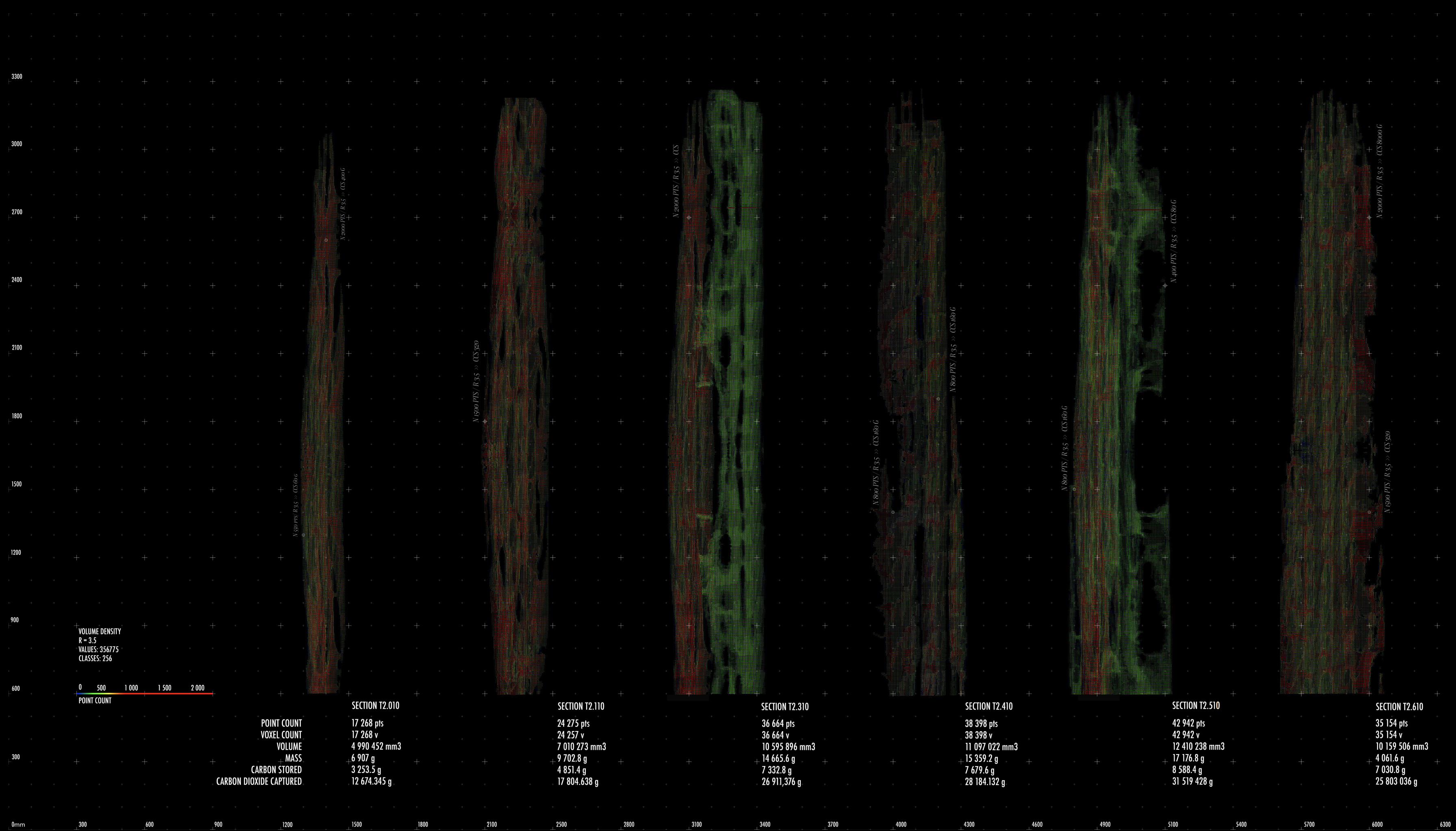

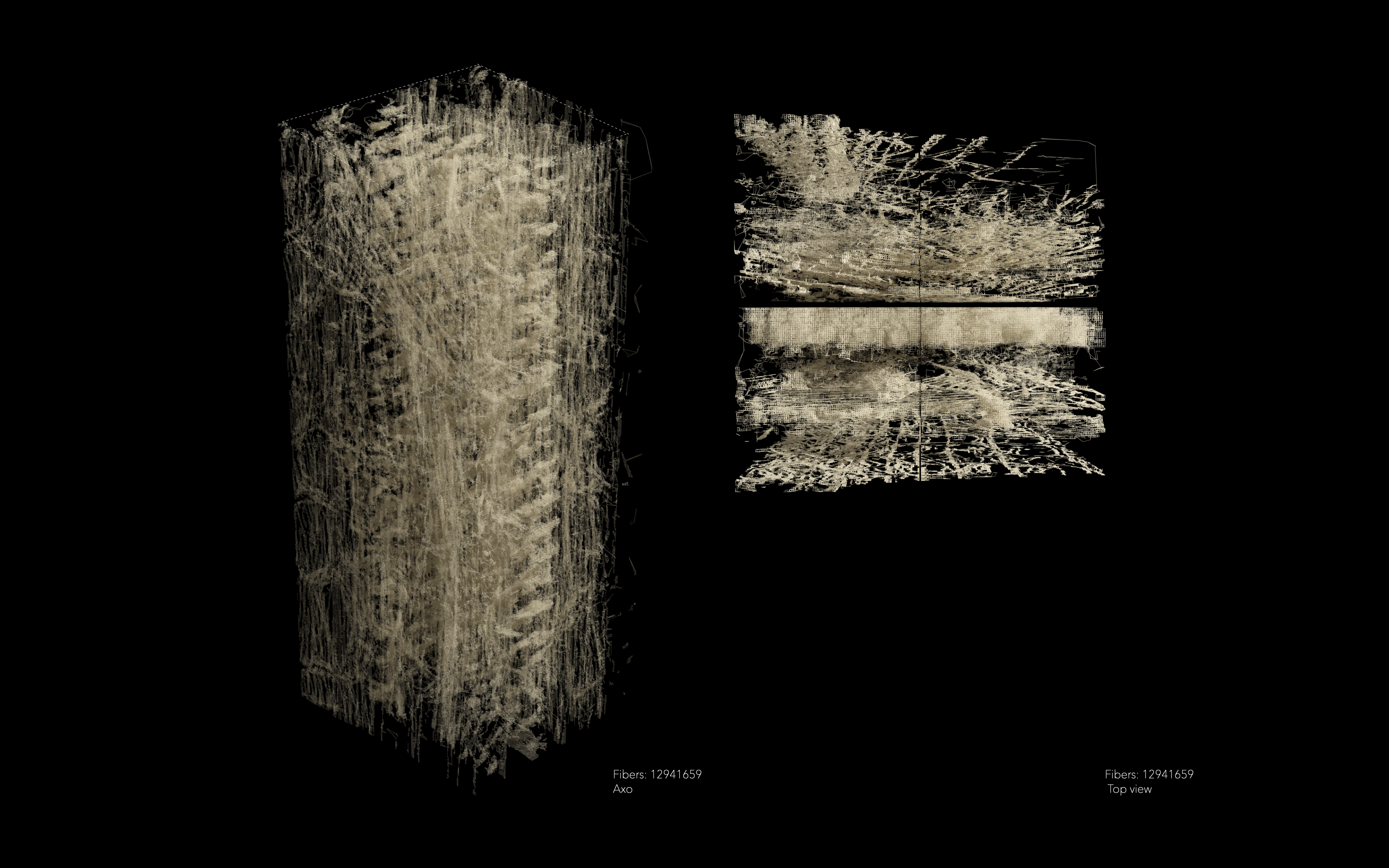

The project proposes the use of Generative Adversarial Networks as a method for extracting a material organisation principle from an existing dataset of timber structure for its further implementation in volumetric models. For this research the StyleGAN2 variant of GAN was chosen in order to develop a technic which would allow an organic data to inform in-organic computational system with its own evolutionary neural network algorithm. A set of experiments was held to train it on all types of cuts and magnifications and the transverse cut in magnification x200 model was selected as the most consistent. This model was used to study the internal and external morphology of timber material organisation with the latent-vector interpolation translation into the Z axis of volumetric structure. In this process basic geometrical data describing the anatomical properties of timber structure of a thousand of timber species were extracted and memorized within a spatial topology. The discontinuous volumetric data set contains such information on the material organisation principles as: allocation of stiff and soft materials within a structure, gradients of fiber densities, as well as variation in hydrophilic properties. This network of curves and surfaces describes the distribution of material as behavioral pattern.Anisotropy of the wooden structure directly affects the distribution of material along the sculpture.

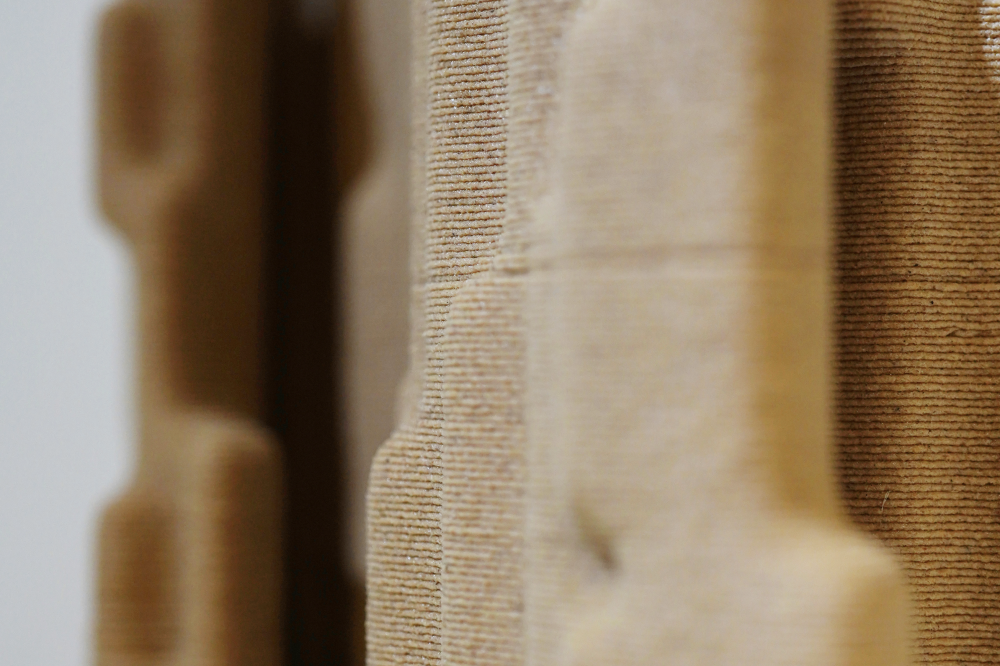

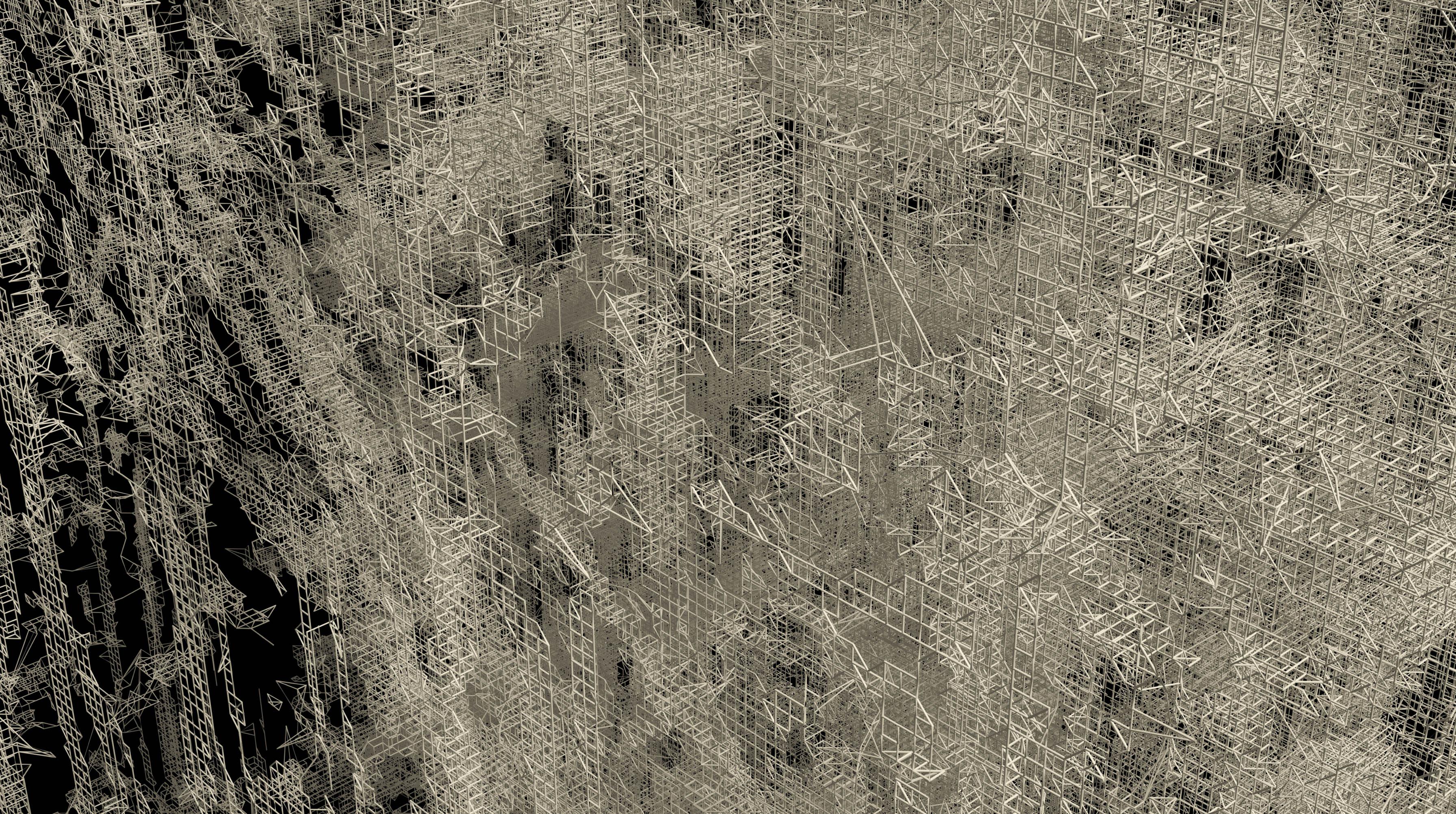

Fabrication technologies such as additive manufacturing allows for the development of adaptive fabrication methods informed by research in material behaviour. Wooden-based material system has been investigated through the large scale 3d printing experiments, suggesting a new regenerative life cycle of matter from the wood in its living state to a recycled wooden material.

Two different material systems have been tested for the development of synthetic prototype. First experiment has been conducted using wooden based filament containing 40% of wood and 60% of recycled PLA plastic. Second experiment has been focused on the development of a water-based material system based on 99% content of wood with 1% of agar-agar as a binding material. For these experiments, sawdust was collected from the local timber industry in Tyrol. Grinded into the fine wood dust, it becomes a perfectly suitable material for 3d printing. For this test a custom-made end-effector has been designed to control the deposition of wooden paste. Material studies provide a new insight on how additive manufacturing can be used to develop novel approaches for timber construction based on bio-printing. Both methods have shown successful results and have been tested at a large scale. For the production of the “Arbor” sculpture wooden based filament with 40% content of wood powder has been chosen as the most suitable for a large-scale rapid prototyping. Water-based 3d printing has been used for the development of a smaller elements printed with a lower speed.

Robotic manufacturing, regenerative life cycles of matter, as well as introduction of machine-learning-based design technic suggest the scenarios where cyborganic wooden structure could be artificially grown. It challenges the processes of growth, decay and ontogenesis, introducing a form of cyborganic living object.

1) J.Vincent, O.A. Bogatyreva, Biomimetics: Its Practice and Theory. Journal of the Royal Society, 2006. pp471

2) https//:archiwood.cirad.fr [Accessed 1 March 2022].

3) F.Hallé, P.Détienne, P.Corbière, ArchiWood: dataset of legacy documents about wood anatomical, morphological, and architectural traits for plant species, 2017.

Project by: Maria Kuptsova

Supervisor: Prof.Claudia Pasquero, Synthetic Landscape Lab, University of Innsbruck

Support in the project development: Korbinian Enzinger, Artem Konevskikh, Riccardo Mangili

Filament: Extrudr

The project was developed at the Synthetic Landscape Lab, University of Innsbruck.